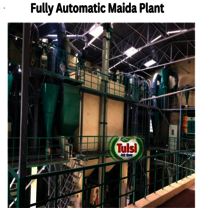

Industrial Maida Flour Mill Plant

Product Details:

- Material Galvanized Steel

- Type Flour Grinding Machine

- Computerized No

- Automatic Yes

- Control System Manual

- Cleaning System Scourer

- Milling System Roller Mill

- Click to View more

Industrial Maida Flour Mill Plant Price And Quantity

- 1 Unit

- 15400000.00 - 60000000.00 INR/Unit

- 1398305.00 INR/Unit

Industrial Maida Flour Mill Plant Product Specifications

- Scourer

- Galvanized Steel

- Lower Energy Consumption, Low Noice, High Efficiency, Compact Structure

- Yes

- No

- Flour Grinding Machine

- Roller Mill

- Manual

Industrial Maida Flour Mill Plant Trade Information

- Mundra

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 2 Unit Per Week

- 1 Months

- Wooden Pallets , Plastic wrap or As Per Requirement ,

- All India

- ISO 9001:2015

Product Description

Maida Flour Mill Plant offered by us, is specially used for grinding the grains into powdered form to make flour. This machine is best known for its peeling process, grind cereals and effective removal of dirt to have high quality end product. This plant is tested under various parameters to ensure its high quality and effectiveness. Maida Flour Mill Plant is available for our eminent clients or customers in bulk at nominal rates. This plant provides smooth and pure flour for further usage.

Product Details:

| Minimum Order Quantity | 1 Unit |

| Usage/Application | Industrial |

| Stone Size | 24 inch |

| Material of Construction(Contact) | Mild Steel |

| Motor Power | 169 to 418 |

| Electricity Connection | Three Phase |

| Operation Mode | Automatic |

In Maida flour mill plant capacity starting from 2 ton per hour.in this plant you will get five product which is Wheat flour, Maida, Rawa, Suji & choker.

Advanced Mill Technology

This flour mill utilizes a robust roller milling system that delivers high-quality maida with precision. Its automatic operation streamlines wheat processing, while the scourer cleaning system ensures raw materials are free from impurities. The manual control interface offers straightforward management and reduced complexity during daily operations.

Efficient and Durable Build

Constructed from galvanized steel, the compact structure is designed for durability and longevity, resisting rust and wear in industrial environments. Lower energy consumption and minimal noise output allow for sustainable and comfortable working conditions. The plants sizable footprint supports continuous production at substantial volumes.

Comprehensive Warranty and Service

A one-year warranty is provided for all core components, ensuring peace of mind and reliable maintenance support. Whether you are a dealer, exporter, or manufacturer, service and spare parts support are readily accessible. The mills free-standing installation simplifies placement, making it adaptable to various factory layouts.

FAQs of Industrial Maida Flour Mill Plant:

Q: How does the cleaning system of this Maida Flour Mill Plant work?

A: The plant uses a scourer cleaning system that effectively removes dust and impurities from wheat before milling, helping to ensure higher flour quality and prolonged machinery lifespan.Q: What is the process for grinding wheat in this plant?

A: Wheat is cleaned via the scourer, then processed through the roller mill system, which crushes and refines the wheat into fine maida flour with high efficiency and low noise operation.Q: When should routine maintenance be performed for optimal performance?

A: Routine maintenance is recommended every few months, depending on usage, to verify proper functioning of the cleaning, roller milling systems, and manual controls. Regular checks ensure lower energy consumption and consistent quality.Q: Where can this flour mill plant be installed?

A: The mill features a free-standing design, allowing installation in industrial spaces, factories, or dedicated milling facilities. Its compact structure fits easily within standard factory layouts.Q: What are the main benefits of using this industrial maida flour mill plant?

A: Key benefits include lower energy consumption, high efficiency, reduced noise, and a compact galvanized steel structure. These attributes support sustainable and reliable flour production at competitive rates.Q: How can the manual control system be operated?

A: Operators manage the plant through a straightforward manual control panel, enabling easy adjustments to processing parameters and quick troubleshooting without computerization.Q: Is computerized control available on this plant model?

A: No, computerized control is not available; the plant is designed with a manual control system for simplicity, reliability, and direct operator oversight.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese