Call Us Now08045805023

Showroom

We are offering the high quality Atta chakki plant for use in commercial and industrial applications. The plant is easy to use and made for an efficient grinding of grains like wheat and others.

Maida Flour Plant is put through a series of tests to verify that it is of the highest quality and effectiveness. The capacity of a Maida flour mill facility starts at 2 tonnes per hour. Maida is a wheat-based white flour from the Indian subcontinent.

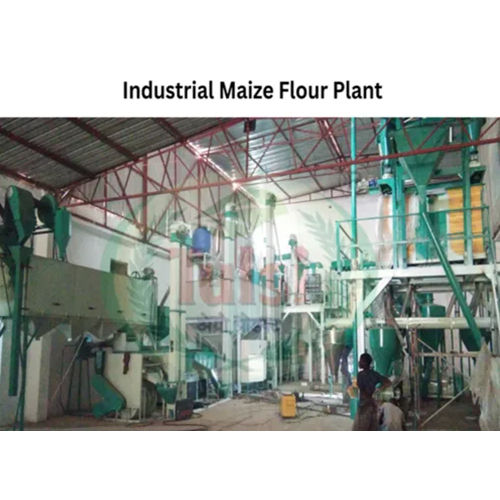

Industrial Maida Plant is mainly used for the production of maida. This plant is great to use and provides soft powdered form of maida. This plant is very effective as well as economical to use. This plant is very much liked and appreciated by our people, in the market.

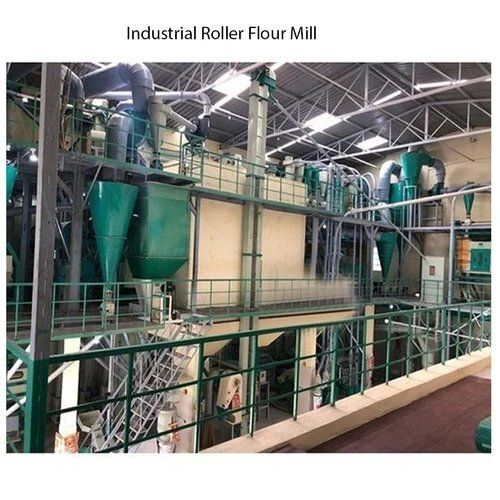

Owing to our rich industrial skills and experience we are dealing in the manufacturing of highly efficient Roller Flour Mill Plant that are commonly used in medium to large-scale food processing industries for the making of impurity-free flour from various food grains.

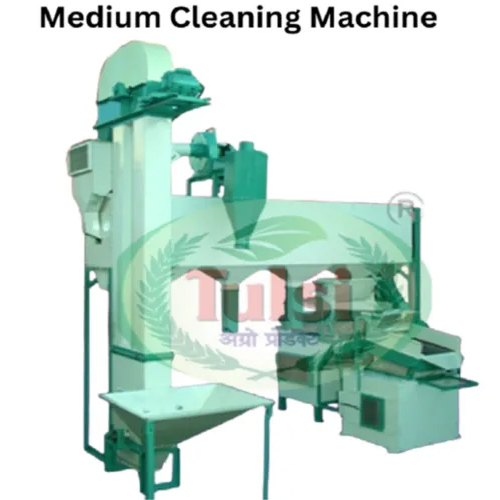

The offered Cleaning machine is made available by us for removing impurities from the grains and making the healthy seed be used for the further processing and use. It is very useful and effective.

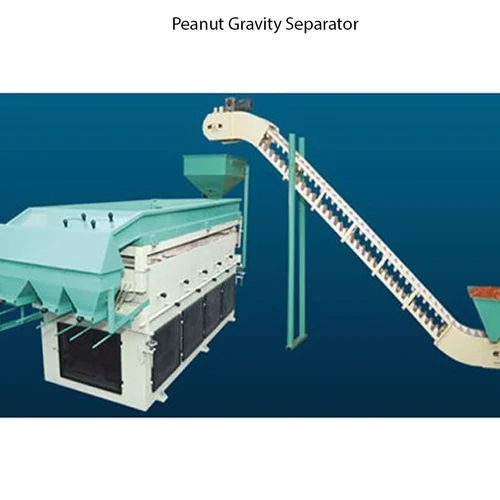

The offered Gravity separator is made available by us in various types and designs. it is easy to operate and made for high durability. The machine is very efficient and made for an effective use.

The grain destoner is very useful and made for effective use in various industrial applications. they are easy to use and made using high quality materials for high durability and long service life.

We are offering the high quality sorting machine for use in various kinds of industrial applications. They are offered by us in various types and designs. It also has a high durability.

We are offering the high quality grain separator for use in various industries and have a highly durable. They are easy to install and operate and have a nice

Grain Seed Grader has three screens for cleaning and grading various crop seeds such as wheat, paddy, and barley. To earn our clients' trust and happiness, we believe in conducting business in a fair and ethical manner. This grader requires very low maintenance and replacement costs.

Filler machines are essential for efficient and precise product packaging across various industries. Our high-quality filler machines are designed to handle a wide range of liquids, powders, granules, and pastes, ensuring consistent and accurate filling every time. We offer versatile models to suit different production scales, from small businesses to large-scale operations. Built with durable materials and advanced technology, our machines prioritize speed, hygiene, and ease of operation. Whether for food, beverages, pharmaceuticals, or cosmetics, our filler machines deliver reliable performance to meet your specific packaging needs.

Back to top

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese